Tegiwa GT86 Rally Build: Widebody Transformation

With our GT86 now featuring its new 4Piston Racing K24-K400 and the major mechanical work complete, it was time to address one of the most visually dramatic aspects of the build – the body kit. For a proper rally car, we needed something that not only looked the business but would provide the necessary clearance for wider wheels and tires while maintaining that aggressive rally aesthetic.

The Body Kit

As with most aspects of this project, we weren’t content to simply follow an existing template.

The appeal of our body kit lies in its dramatic arch flares and purposeful stance, but for our rally application, we needed to ensure perfect fitment and durability. This meant custom adjustments throughout the development and installation process, tailoring each piece to flow seamlessly into the already existing body work.

Rather than accepting the typical bolted-on appearance that many body kits suffer from, we took the extra step to smooth over all of the mounting holes. This wasn’t just about aesthetics – though the seamless finish certainly improves the overall look – it was also a practical decision that would pay dividends later.

By eliminating the visible bolt holes and creating smooth transitions between the kit and the original bodywork, we achieved two key objectives. First, the finished product has a much more professional, OEM+ appearance. Second, and perhaps more importantly, this smooth finish provides the perfect foundation for the our livery to be applied.

Anyone who’s attempted to wrap over irregular surfaces or protruding hardware knows the challenges involved. By creating continuous, smooth surfaces, we’ve made the wrapping process significantly easier and ensured a more durable, long-lasting finish that can withstand the rigours of rally competition.

The Wheels Dilemma and Livery Preview

With the widebody kit installed, we faced a classic modified car problem – the OEM wheels looked absolutely tiny tucked deep within the new arch extensions. This temporary mismatch actually made it quite difficult to visualise what the finished car would look like, as the proportions were completely thrown off.

Fortunately, work had already begun on our rally livery design. Created in-house, the livery concept gave us our first real glimpse of what the finished GT86 would become. Even in digital form, it was clear that this wasn’t going to be just another modified GT86 – this was evolving into something special.

The Transformation

The magic really happened over the next few days as all the elements came together simultaneously. The livery installation was the catalyst that transformed the entire project. Suddenly, what had been a collection of individual modifications became a cohesive package all bundled into one – an actual rally car that looked like it belonged on a special stage rather than a workshop.

The custom front light pod, which had looked somewhat out of place on the stock body, now made perfect sense as part of the rally-inspired package. Every modification now complemented the others, and our hard work was now starting to come together for the first time.

Braid Fullrace Wheels: Form Meets Function

The final piece of the puzzle came with the installation of our Braid Fullrace wheels. One of the major advantages of going with Braid is that their wheels are made to order, which meant we could choose the exact specification we needed. We went with 17×8 ET2 on both axles – a setup that wouldn’t be virtually impossible with off-the-shelf wheels but was perfect for our wide body rally application.

The switch to Braids brought multiple benefits. Most obviously, they filled the widebody arches properly, giving the car the aggressive stance it was always meant to have. But beyond the visual improvement, the Braids also represent a significant performance upgrade over the stock wheels. The reduction in unsprung weight will improve suspension response and overall handling characteristics – crucial for a car that needs to perform on demanding rally stages.

When it came to rubber, we selected Yokohama A051T tyres in 215/45/17 – a size that balances performance with practicality. The Yokohama A051T is a proven choice for rally applications, as we have previously had great experience with these tyres on our Civic FN2 rally car.

Motorsport UK Sign-Off

Before we can even think about competitive rallying, there was one crucial milestone to clear – getting the car signed off by Motorsport UK. This involved a thorough inspection by a qualified scrutineer to ensure our GT86 meets all the necessary safety and technical regulations for competition use.

Think of it as getting a passport for competition – the sign-off documentation is essentially proof that the car is safe and legal to compete. Without it, you’re not getting through the gates at any event, let alone onto the stage. The scrutineer went through everything with a fine-tooth comb: safety equipment, roll cage installation, fuel system, electrical setup, and all the technical modifications we’d made.

Getting that sign-off was a massive relief and validation that all the work we’d put into the build was up to standard. Now we have the official rally passport that we’ll need to present at every event before the usual pre-competition scrutineering process.

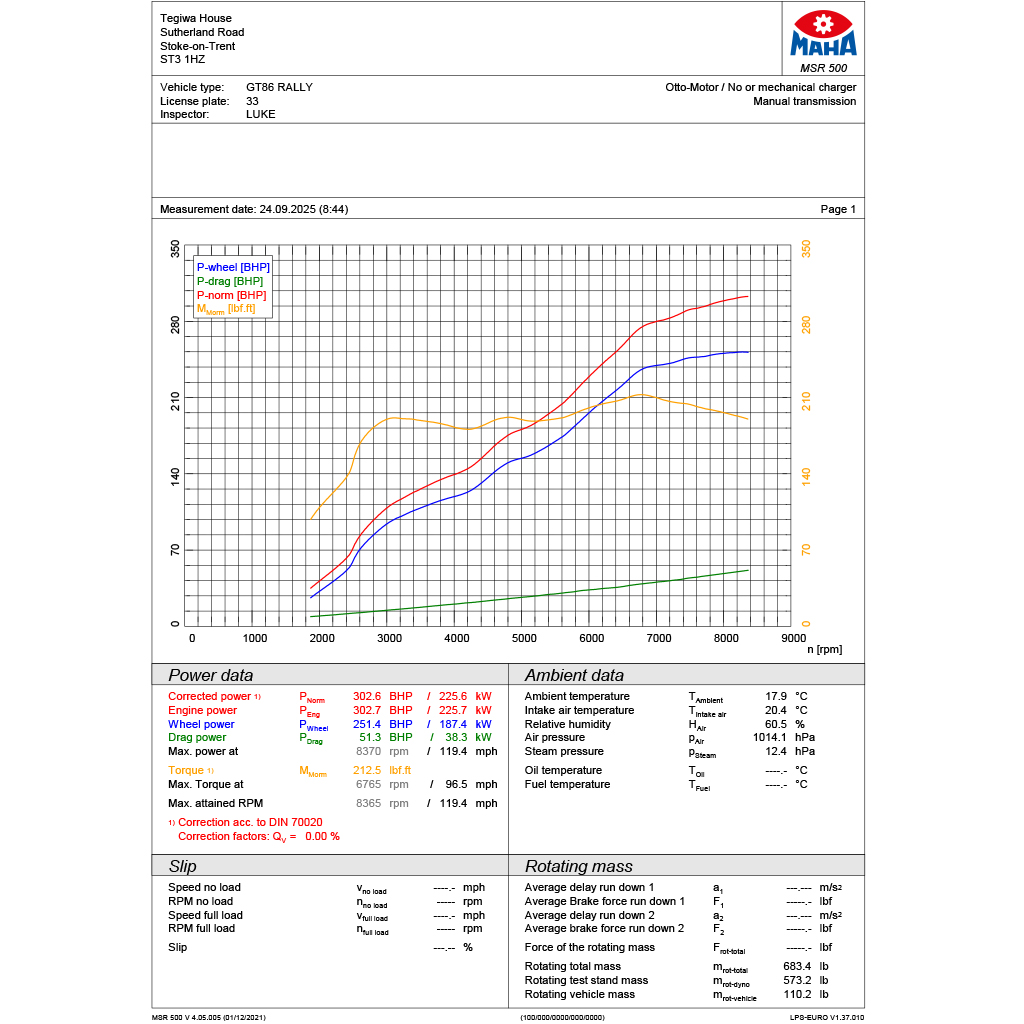

Tuning by TDP

With the visual transformation complete, it was time to see what power our K-swapped GT86 could actually produce. We enlisted Robbie at TDP to handle the mapping – a decision that proved absolutely spot on. With over 10 years of experience tuning Haltech products, Robbie was able to work his magic remotely, which made the whole process incredibly smooth.

The initial results were impressive: 302.6bhp with the rev limit set conservatively at 8,300rpm to keep everything safe during this development phase. The 4Piston K-series engine clearly has much more to give, but we’ve already identified the main restriction – the stock GT86 65mm throttle body is choking the engine at higher RPM.

The solution is already on order from Haltech: a Bosch electronic throttle body in the largest available 82mm size. This will integrate perfectly with our Elite 1500 ECU’s drive-by-wire capabilities and should unlock significantly more power from the K-series setup.

The issue with the stock throttle body is simple – it’s sized for the original FA20 boxer engine, not a high-revving K-series that’s making over 300bhp. At higher RPM, the small diameter becomes a bottleneck, restricting airflow just when the engine needs it most. The 82mm Bosch unit will more than double the cross-sectional area, allowing the engine to breathe properly throughout the entire rev range. Combined with the improved throttle response that electronic control offers, we’re expecting to see gains right across the power curve – not just at the top end.

Perhaps the most surprising discovery from it’s recent weigh in is that the car tips the scales at exactly the same 1,235kg as it did when we started the project. This might seem impossible given everything we’ve added – a full roll cage, rally accessories, and all the competition safety equipment. The power-to-weight transformation tells the real story of what we’ve achieved. The stock GT86 managed 150bhp per tonne, which was adequate but hardly thrilling. Our K-swapped version now delivers 244bhp per tonne – a 63% improvement that should translate into dramatically better acceleration and overall performance.

What’s Next?

The GT86 has come a long way from the high-mileage hero we started with. The widebody transformation has given it proper rally car stance, the livery makes it look like it belongs on the rally stage, and we’ve now got over 300bhp on tap.

But there’s only one way to find out if we’ve built a genuine rally weapon – we need to get it out on track. Our first proper test session is booked in at Knockhill, which will be the car’s first real shakedown since the build was completed.

All the planning, modifications, and development work comes down to how the car actually performs when we start pushing it. No doubt we’ll discover things that need tweaking, adjusting, or completely rethinking – that’s all part of the development process.

The transformation might be complete, but the real work is about to begin. We’ll let you know how the testing goes – and with our first rally already booked for November 1st at Oulton Park, there’s no time to waste.