Hawk Performance Brake Compounds: Choosing the Right Pad for Your Needs

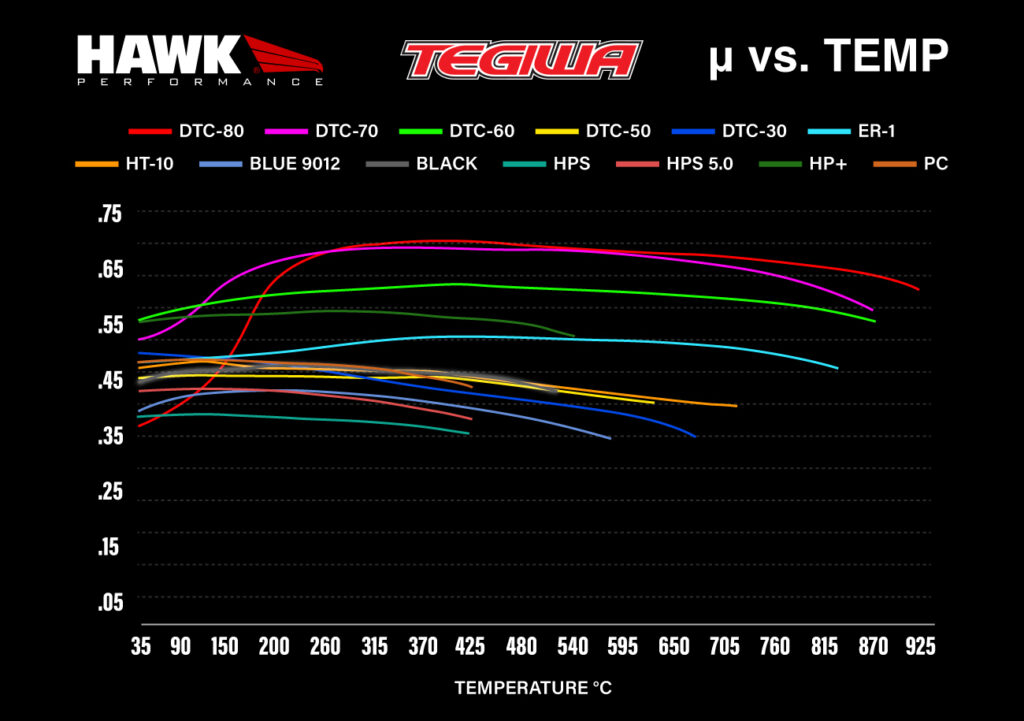

Hawk Performance is a leading manufacturer of high-performance brake pads for motorsports applications. Their brake pads are designed to deliver exceptional stopping power and fade resistance under extreme conditions. But with a variety of compounds available, choosing the right one for your specific needs can be a challenge.

Understanding Brake Pad Compounds

The performance of a brake pad is largely determined by the compound it’s made from. Different compounds are formulated to operate within specific temperature ranges. Here’s a breakdown of the different Hawk Performance brake compounds and their ideal applications:

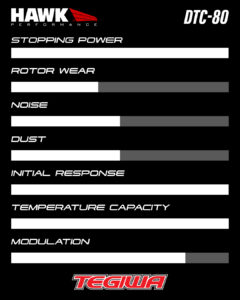

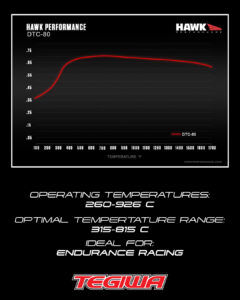

DTC-80

Intended for the hardest braking circuits where the most demanding brake products are required, DTC-80 is a compound engineered for use on all circle track and road racing venues where a high torque, high temperature-resilient friction material is a must. With a formulated flat coefficient of friction at high temperature levels, DTC-80 provides consistent performance corner after corner. Track tested and proven effective, this formulation offers lower wear rates and higher torque values than other competitive materials on the market today. The end results are better car control, more confident brake zone feel, and stunningly predictable performance.

- 260-926 C operating temperatures

- 315-815 C optimal temperature range

- High initial bite

- Consistent brake torque level over temperature range

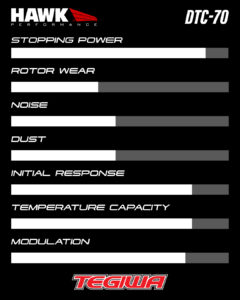

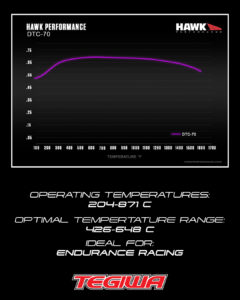

DTC-70

DTC-70 was engineered with extremely high torque and highly aggressive initial bite for cars with high deceleration rates, with or without downforce. With superior release and control characteristics, it’s a winning race solution on its own or as split friction with DTC-60.

- 204-871 C operating temperatures

- 426-648 C optimal temperature range

- High performance high torque compound

- Superior rotor and pad wear

- Excellent modulation and release characteristics

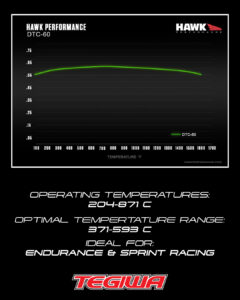

DTC-60

Running with extremely high deceleration rates and increased downforce poses different challenges, so Hawk designed DTC-60. Recommended with DTC-70 when split friction between axles is desired, it has excellent modulation and release characteristics.

- 204-871 C operating temperatures

- 371-593 C optimal temperature range

- Superior release and torque control

- Very low abrasive rotor wear

- Popular choice on lightweight front axle applications, with or without ABS

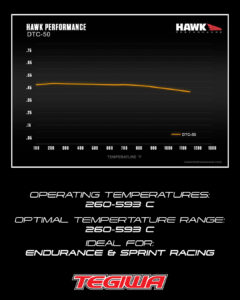

DTC-50

Hawk’s DTC-50 is what racers have been asking for: a pad that can be used as a split compound for tuning, and an endurance compound that can be used at the highest levels of racing. DTC-50 was developed through extensive testing, giving racers a pad that enhances our line of Dynamic Torque Control products and bridges the temperature and brake torque range between our current DTC-30 to DTC-60 race pads. This new compound offers consistent performance across a wide range of temperatures, while providing very high torque and aggressive initial bite.

- 260-593 C operating temperatures

- 260-593 C optimal temperature range

- Aggressive initial bite

- Excellent modulation and release characteristics

- High temperature fade resistance

- Designed for high deceleration rates

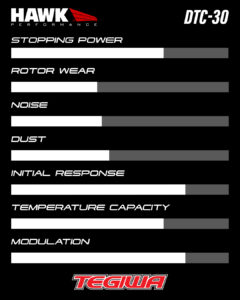

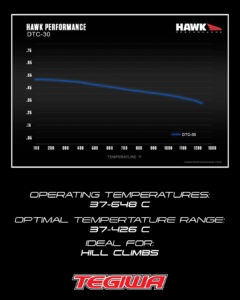

DTC-30

DTC-30 is a controllable torque, multi-purpose compound, proven effective in a range of series. It delivers superior release characteristics and smooth pedal feel and initial bite for dirt and circle tracks, NASCAR modified, drag racing, trophy trucks, pro buggies, and more.

- 37-658 C operating temperatures

- 37-426 C optimal temperature range

- Consistent, smooth braking

- Good cold effectiveness

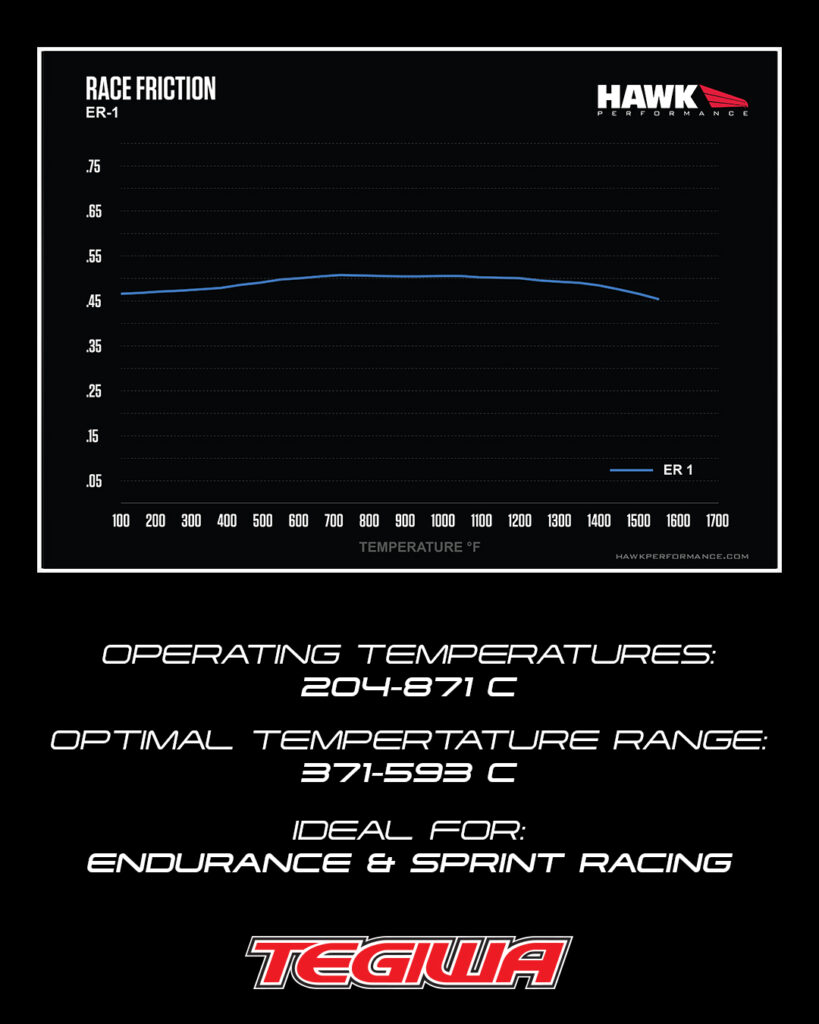

ER-1

ER-1 has been developed by Hawk Performance for the endurance racing market with a simple goal; offer a higher coefficient of friction than competing endurance pads while maintaining matched or improved lifespan. Years of testing across America’s most prestigious races has resulted in a well-rounded compound that offers ideal modulation and pedal communication, with ground breaking friction stability across a thermal range as high as 1,600°F. This consistency of performance, hour after hour, makes it ideal for not only endurance racing, but HPDE, track days, time trials and even sprint racing.

- 204-871 C operating temperatures

- 371-593 C optimal temperatures

- Superior pad & rotor wear

- Consistent medium-to-high friction

- Specific emphasis on modulation, release and pedal communication

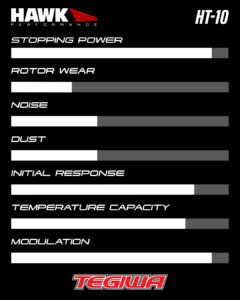

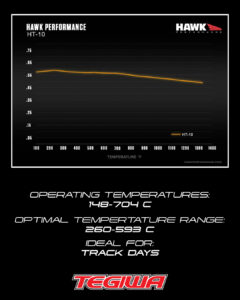

HT-10

For linear in-braking in a medium temperature range, look no further than HT-10. It delivers smooth, controllable initial bite and consistent pedal feel. It’s no wonder Hawk’s legacy friction products have become the choice of champions.

- 148-704 C operating temperatures

- 260-595 C optimal temperature range

- Good static and dynamic coefficient

- Excellent modulation characteristics

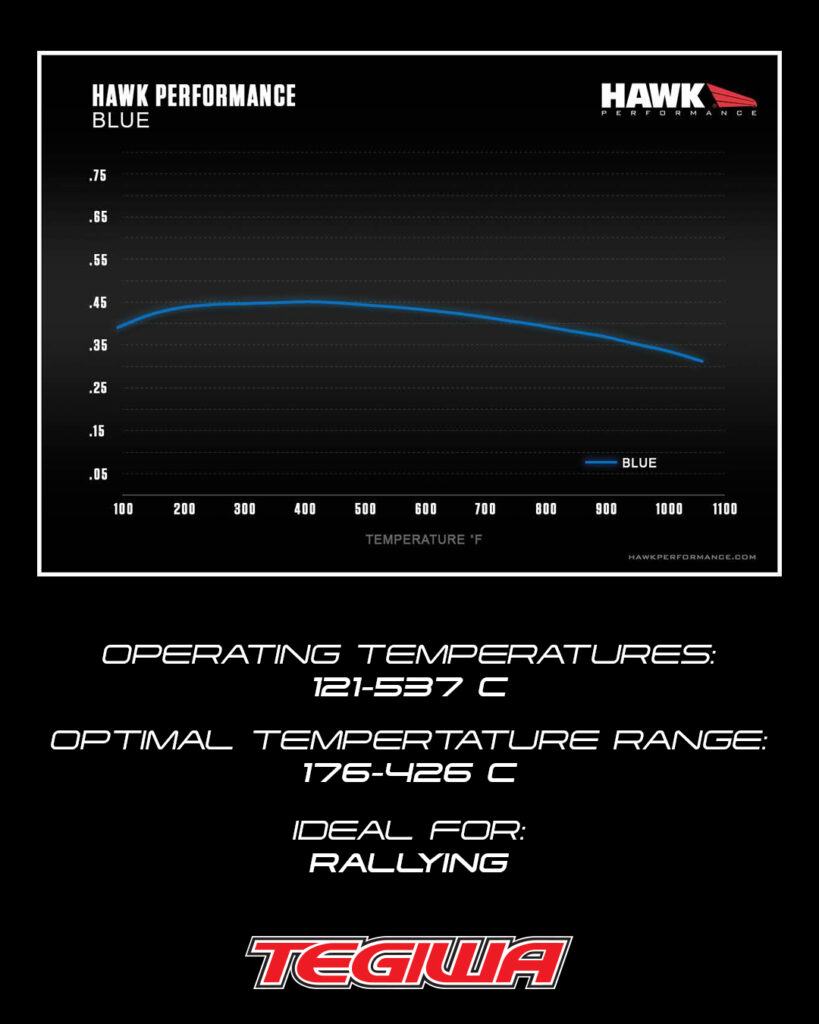

Blue 9012

Designed as an entry level endurance compound, there’s nothing second-string about Hawk’s Blue 9012 race compound. Easier to bed in and delivering excellent pad and rotor life, Blue 9012 is a medium torque pad developed specifically for Road, Rally and Circle Track racing.

- 121-537 C operating temperatures

- 176-426 C operating temperatures

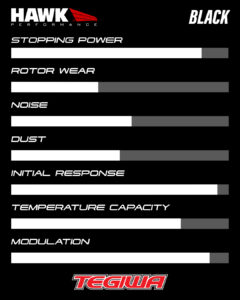

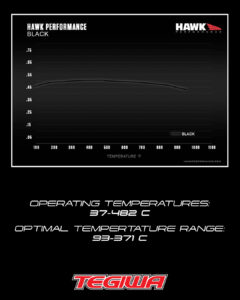

Black

Working with racers at all levels, Hawk know the challenges of getting your car to the track. Black was designed as an all purpose race compound, low cost race pad. It’s good cold effectiveness is up to the task on a wide range of tracks.

- 37-482 C operating temperatures

- 93-371 C operating temperatures

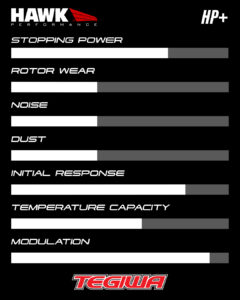

HP+

This compound utilises unique Ferro-Carbon, high-tech friction material which is developed for sport driving. This formulation offers lower wear rates and higher torque values than competitive materials.

- 37-426 C operating temperatures

- 148-315 C optimal temperature range

- Low to mid temperature range

- Fade resistant

- Smooth & predictable torque

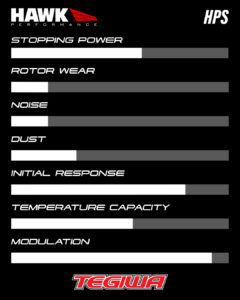

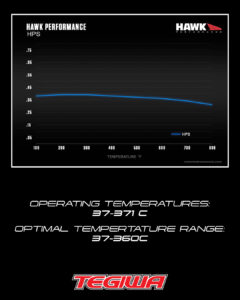

HPS (High Performance Street)

High Performance Street disc brake pads are legendary for increasing stopping power on street-legal vehicles, and increasing the performance of your vehicle’s braking system is easy when you choose Hawk Performance Street HPS braking compound. The High Performance Street compound offers a higher coefficient of friction over stock brake pads, and can provide you 20-40% more stopping power and higher resistance to brake fade than most standard replacement pads. Less fade means you will have better pedal feel and more consistent performance in a durable brake pad that generates less dust.

- 37-371 C operating temperatures

- 37-360 C optimal temperature range

- Smooth braking feel

- Excellent for spirited driving

- Gentle on rotors and extended pad life

- Consistent brake release characteristics

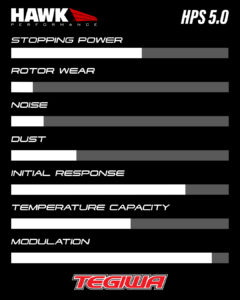

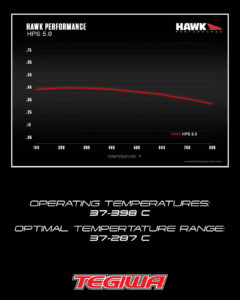

HPS 5.0

For years, engine builders have been pushing motors to the limits of their ability, and at Hawk Performance, we’re closer than ever to pushing the ABS Rev Limiter to its limits. High Performance Street 5.0 pads give your vehicle the greatest stopping power and pedal feel without compromising ABS. HPS 5.0 is a Ferro-Carbon compound that provides advanced braking characteristics to enhance the driving experience. This compound combines the safety and quality of aerospace design with the braking technology of motorsports. The results are shorter stopping distances, improved performance under heavy braking conditions, and street car friendly characteristics.

- 37-398 C operating temperatures

- 37-287 C optimal temperature range

- Aggressive torque

- Great rotor & pad wear life

- Smooth & predictable control

- Consistent brake release characteristics for a smooth braking feel

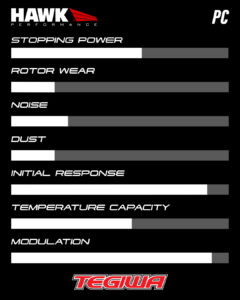

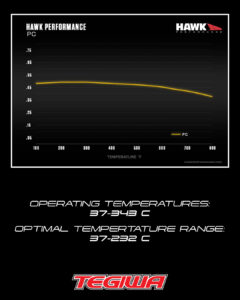

PC (Performance Ceramic)

Hawk understands the needs of today’s ceramic brake pad users and has specifically formulated our composite material to meet – and beat – the stringent low noise, ultra-low dust performance standards they have set. Engineered to reduce brake NVH (Noise, Vibration and Harshness), Performance Ceramic is a premium disc brake pad that delivers excellent performance mile after mile. Providing a linear friction profile that allows your vehicle’s ABS system to operate most effectively, our unique compound has the advantage of never sacrificing power to achieve traditional ceramic pad attributes. With Hawk’s PC, you can expect reduced brake pad wear, longer rotor life, and our quietest ride ever.

- 37-343 C operating temperatures

- 37-232 C optimal temperature range

- Extremely quiet

- Ultra-low dust

- Improved stopping power

- Gentle on rotors for extended pad life

- Stable friction output

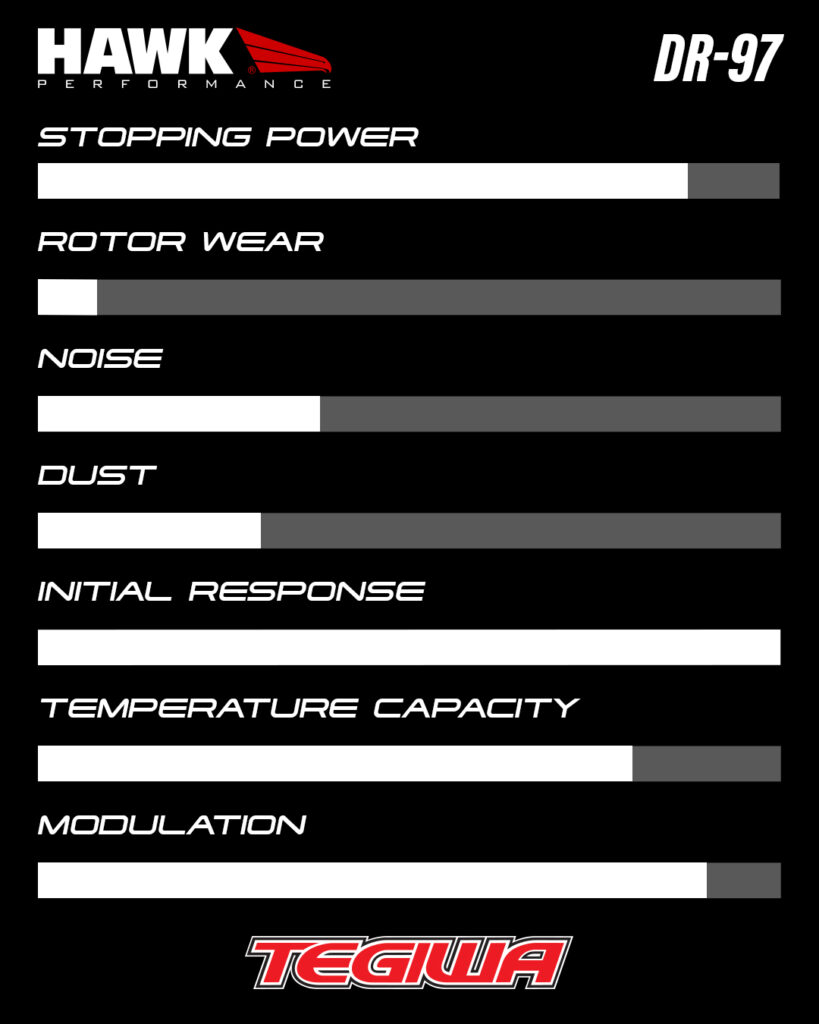

DR-97 (Drag racing)

Excellent static and dynamic co-efficient of friction with smooth, linear torque. With these pads you can expect low pad and rotor wear. It is specifically designed for use in drag racing applications.

Choosing the Right Brake Compound

The best brake compound for your car will depend on how you plan to use it. Here are some factors to consider:

-

Type of driving: If you plan to take your car to the track, you’ll need a compound that can handle high temperatures without suffering fade. For daily street driving, a more moderate compound that doesn’t need to handle high temperatures is appropriate.

-

Driving style: If you drive aggressively straight from the word go, you’ll need a compound that can provide good stopping power and fade resistance from cold. If you can take time to warm up the pads then a compound like DTC-80 might work best.

Additional Considerations

It’s important to note that Hawk Performance brake pads are not compatible with carbon ceramic rotors. They are designed to work with iron/metal rotors.

By understanding the different Hawk Performance brake compounds and considering your specific needs, you can choose the right pad to optimise the braking performance of your car. Get yours now at Tegiwa.com!